Refinery Maintenance Deferral: The Perfect Storm

Link to article: https://stillwaterassociates.com/refinery-maintenance-deferral-the-perfect-storm/

November 8, 2022

In the wake of skyrocketing gasoline prices in California, refinery maintenance has been quite the hot topic. To dive right in, there are 4 types of refinery maintenance as defined by the U.S. Energy Information Administration (EIA):

- Planned refinery turnarounds – major maintenance or overhaul activities which occur on a set schedule

- Planned shutdowns – targeted shutdown with a smaller scope than a full turnaround

- Unplanned shutdowns – unexpected but do not require emergency action

- Emergency shutdowns – one or more units or the entire refinery shut down immediately without any warning(1)

To better understand the considerations when planning for maintenance, as well as why a refiner might choose to defer maintenance, I talked with two of Stillwater’s Senior Associates, each with over 30 years of experience working in refineries.

What is involved in planning for maintenance?

Large amounts of capital need to be set aside, contractors and equipment need to be lined up in advance, and contracts need to be in place to make up for the lack of supply while units are down. Contracts will be established with third parties to purchase needed volumes of finished products to meet existing commitments. Inventory can also be built up when planning for an outage, but spare tankage is typically limited.

Why might a refiner choose to defer maintenance?

Deferring maintenance brings on a certain amount of risk as there is a higher chance that unplanned work will need to be done. There is also risk that the quality and reliability of product will suffer. Cost saving/reduction efforts are typically the main reason to defer maintenance. In recent history, maintenance was deferred during COVID because refineries were losing money, so there wasn’t excess capital to spend on maintenance. There also weren’t enough contractors to complete the needed work. At the end of 2021, when many began considering COVID “over,” planned maintenance was scheduled for spring of 2022, but then Russia invaded Ukraine, upsetting the supply and demand balances for refined products, and maintenance was rescheduled for fall of 2022.

The perfect storm

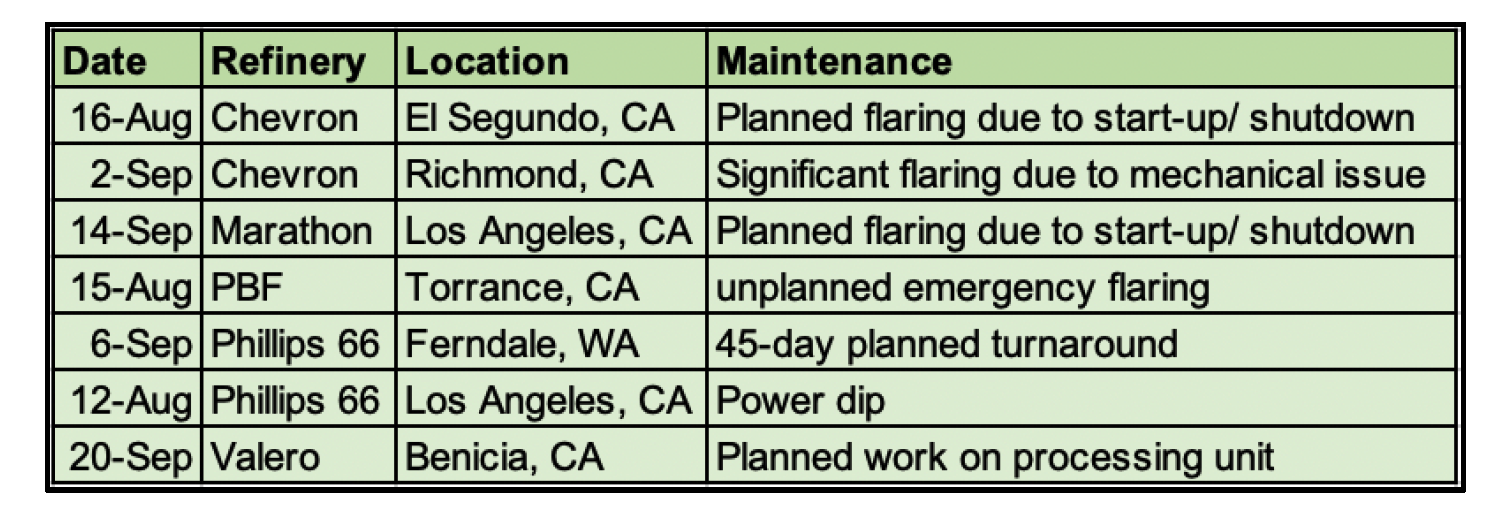

As mentioned above, when maintenance is deferred, there is a higher likelihood of unplanned problems arising. According to the Refinery Maintenance Report released by OPIS, the following outages occurred recently(2):

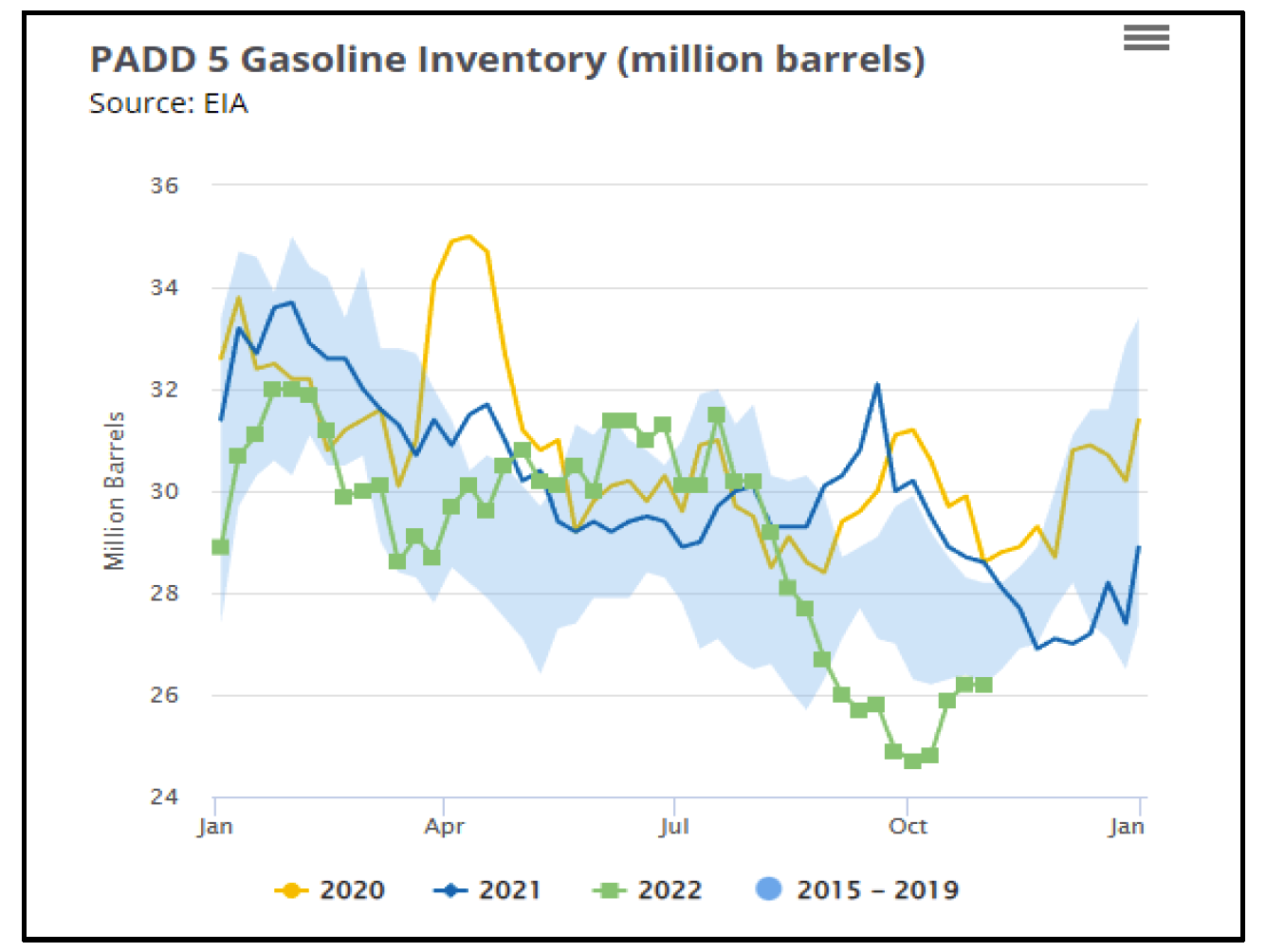

Normally, product can be pulled from inventory to help cover the volume lost by these outages. However, in the last few months, PADD 5 inventories have been at record lows:

Normally, product can be pulled from inventory to help cover the volume lost by these outages. However, in the last few months, PADD 5 inventories have been at record lows:

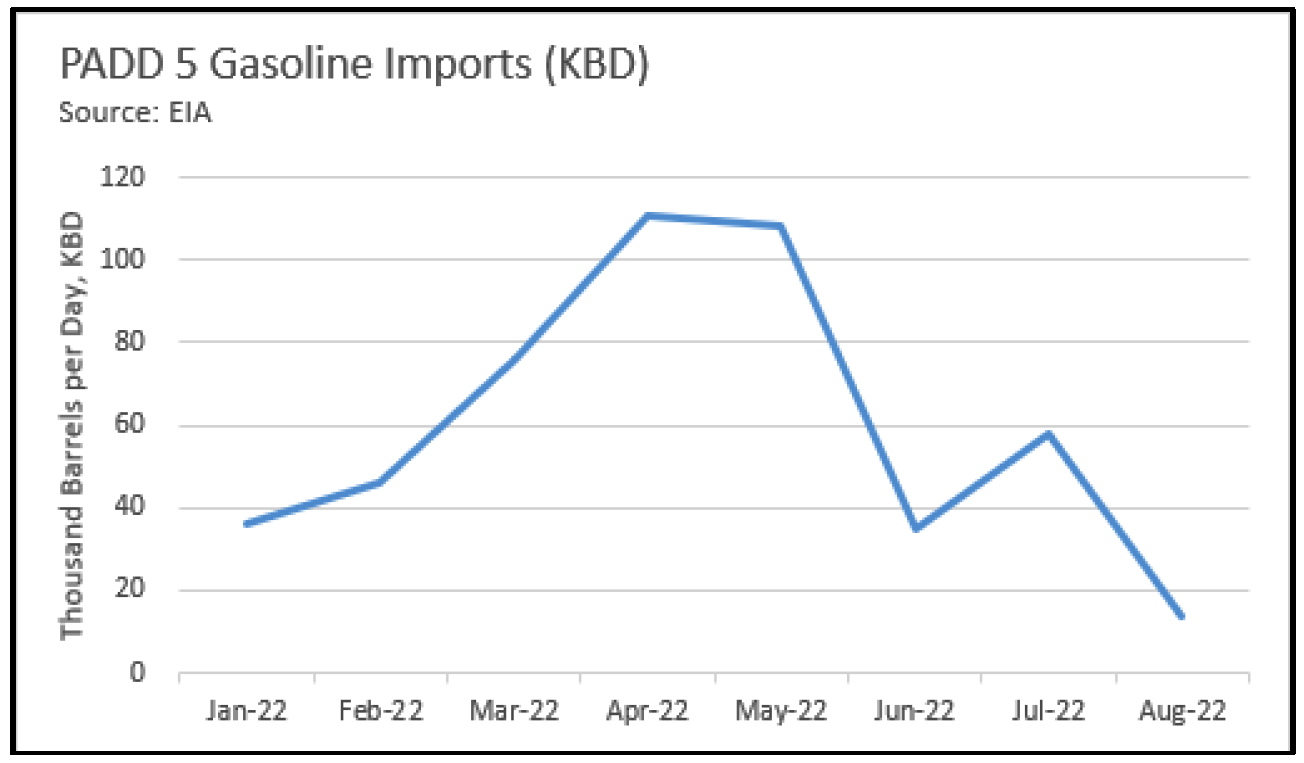

Imports can also be used to cover lost production during outages. The following import data from EIA has a three-month lag but shows a large decrease in imports leading into the month of August:

Unplanned maintenance, low inventory, or depressed imports are relatively common occurrences individually. But combining all three issues at the same time has created the perfect storm, contributing to the recent gasoline price spikes.

Dive deeper: check out Stillwater’s analysis around the survivability of refining and refining capacity in the U.S. going forward in the November edition of our LCFS Newsletter.